This manual provides comprehensive instructions for cleaning and sanitizing your Manitowoc ice machine. It covers essential steps for maintaining optimal performance and ensuring food safety. Regular cleaning is crucial to extend the life of your ice machine and prevent the growth of bacteria. Follow these guidelines to keep your ice machine in top condition.

Introduction

This manual is your comprehensive guide to maintaining a clean and hygienic Manitowoc ice machine. It provides step-by-step instructions for cleaning and sanitizing your machine, ensuring that the ice produced is safe for consumption and that your machine operates efficiently. A clean ice machine is essential for producing high-quality ice and promoting a healthy environment. This manual will help you understand the importance of regular cleaning, the necessary materials, and the proper procedures for cleaning and sanitizing your Manitowoc ice machine. Whether you are a seasoned professional or a new owner, this manual provides the knowledge and tools you need to keep your ice machine clean and in peak condition. Follow these instructions carefully to ensure the longevity and optimal performance of your Manitowoc ice machine.

Importance of Cleaning

Regular cleaning of your Manitowoc ice machine is essential for a variety of reasons, directly impacting both hygiene and machine performance. Firstly, cleaning prevents the growth of bacteria and mold, which can contaminate the ice and make it unsafe for consumption. This is particularly important in food service establishments where hygiene standards are paramount. Secondly, a clean ice machine operates more efficiently, as mineral deposits and other contaminants can hinder the machine’s performance and lead to premature wear and tear. Regular cleaning helps to maintain the machine’s optimal performance, ensuring consistent and efficient ice production. Additionally, a clean ice machine contributes to a more pleasant work environment, eliminating potential odors and creating a more hygienic atmosphere. In short, regular cleaning of your Manitowoc ice machine is essential for maintaining food safety, maximizing machine longevity, and ensuring a clean and professional work environment.

Cleaning Frequency

The frequency of cleaning your Manitowoc ice machine depends on several factors, including the machine’s usage, water quality, and environmental conditions. However, a general guideline is to perform a thorough cleaning and sanitizing every six months. This helps to maintain optimal hygiene and prevent the buildup of contaminants that can affect ice quality and machine performance. In addition to the six-month deep cleaning, a preventative maintenance cleaning/sanitizing is recommended every 30 days. This involves running a cleaning cycle with a specialized cleaner or sanitizer, which helps to prevent the buildup of mineral deposits and bacteria. For high-usage environments, such as restaurants and bars, more frequent cleaning may be necessary, perhaps even weekly or bi-weekly. Regular visual inspection of the ice machine can help determine the need for more frequent cleaning. If you notice any signs of mineral buildup, discoloration, or odor, it’s a good indication that a cleaning is needed. By adhering to these cleaning schedules, you can ensure your Manitowoc ice machine remains clean, hygienic, and operating at its best.

Materials Needed

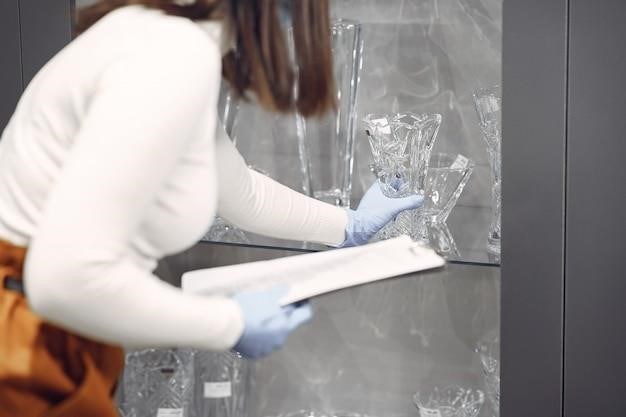

To effectively clean and sanitize your Manitowoc ice machine, you’ll need a few essential materials. First and foremost, you’ll need Manitowoc Ice Machine Cleaner and Sanitizer. These specially formulated products are designed for use with Manitowoc ice machines and are available in convenient 16 oz. (473 ml) bottles. They ensure safe and effective cleaning without damaging the machine. You’ll also need a clean, soft-bristled brush or sponge to scrub the interior components. A clean, non-abrasive cloth is essential for wiping down surfaces. For cleaning the condenser, a vacuum cleaner with a brush attachment is highly recommended. You’ll also need a container for mixing the cleaning solution. A measuring cup or graduated cylinder will help ensure the correct proportions of cleaner and water. Finally, a pair of rubber gloves is essential for protecting your hands from the cleaning solution. By gathering these materials, you’ll be well-prepared to clean and sanitize your Manitowoc ice machine effectively and safely.

Step-by-Step Cleaning Process

Cleaning your Manitowoc ice machine is a straightforward process that can be completed in a few simple steps. First, ensure the machine is turned off and disconnected from the power source. Then, turn off the water supply to the ice maker. Remove the front panels to access the interior components. Now, carefully remove all ice from the bin or dispenser. With the interior accessible, you can begin cleaning. Use the Manitowoc Ice Machine Cleaner and Sanitizer as per the instructions provided in the user manual. Ensure the solution is properly mixed with water before applying it to the surfaces. Scrub the interior components, including the evaporator, water trough, and ice bin, using a clean brush or sponge. Rinse thoroughly with clean water to remove any cleaning solution residue. Next, sanitize the machine using the Manitowoc Ice Machine Sanitizer. Follow the instructions provided in the user manual for the correct dilution and application process. Allow the sanitizer to dwell for the recommended time before rinsing with clean water. After completing the cleaning and sanitizing process, reassemble the machine and reconnect the power source. Finally, turn the water supply back on and allow the machine to run through a complete ice-making cycle before using it. By following these steps, you can ensure that your Manitowoc ice machine is clean and sanitary, producing fresh and pure ice.

Shutting Down and Accessing the Machine

Before you begin cleaning your Manitowoc ice machine, it’s essential to shut it down properly and gain access to its internal components. First, turn off the ice machine by flipping the toggle switch to the OFF position. Next, ensure the machine is disconnected from the power source. This step is crucial for safety and to prevent any electrical hazards during the cleaning process. Once the power is off, turn off the water supply to the ice maker. This can usually be done by using a nearby shut-off valve, preventing water from flowing into the machine during the cleaning process. Now, you can access the machine’s interior components. Start by removing the front panels. Carefully detach the panels, following the instructions in the user manual. This will allow you to reach the evaporator, water trough, and ice bin, which need to be cleaned and sanitized. Ensure you remove all ice from the bin or dispenser before proceeding with the cleaning process. This will make it easier to clean the machine and prevent any ice from interfering with the cleaning process. With the machine shut down, the water supply turned off, and the front panels removed, you are now ready to begin the cleaning and sanitizing process.

Cleaning the Interior

Once you’ve gained access to the interior of your Manitowoc ice machine, it’s time to clean the internal components. This involves cleaning the evaporator, the water trough, and the ice bin. Start by cleaning the evaporator. This is the core component of your ice machine, responsible for freezing water into ice. Use a solution of Manitowoc ice machine cleaner and water, following the recommended ratio. Apply the solution to the evaporator using a soft-bristled brush. Carefully scrub the surface, removing any dirt, grime, or mineral deposits. Rinse the evaporator thoroughly with clean water to remove any remaining cleaning solution. Next, move on to the water trough. This component collects water before it is frozen into ice. Use a sponge or a soft cloth to wipe down the water trough, removing any debris or buildup. Rinse the trough with clean water and allow it to dry completely. Finally, clean the ice bin. This component holds the ice once it has been produced. Use a sponge or a soft cloth to wipe down the ice bin, removing any dirt or ice remnants. Rinse the bin thoroughly with clean water and allow it to dry completely. It’s important to follow the specific instructions provided in your Manitowoc ice machine manual regarding cleaning solutions and procedures. This ensures that you are using the correct products and techniques for your particular model. Always remember to clean the ice machine thoroughly after each use to maintain optimal performance and prevent the growth of bacteria.

Sanitizing the Machine

After cleaning the interior of your Manitowoc ice machine, it’s essential to sanitize it to eliminate any remaining bacteria. Sanitizing is crucial for maintaining food safety and ensuring that the ice produced is hygienic. Manitowoc recommends using their approved ice machine sanitizer for this process. The sanitizer comes in convenient bottles and is specifically designed to work effectively with Manitowoc ice machines. Start by mixing a solution of Manitowoc ice machine sanitizer and water, following the recommended ratio. Apply this solution to the evaporator, water trough, and ice bin. Use a sponge or a soft cloth to ensure the sanitizer reaches all surfaces. Allow the sanitizer to sit for the recommended time, as specified on the product label. This allows the sanitizer to effectively kill any bacteria present. Once the recommended time has elapsed, rinse all surfaces thoroughly with clean water to remove any remaining sanitizer. It’s crucial to follow the specific instructions for your Manitowoc ice machine model regarding sanitizing procedures. This ensures that you are using the correct sanitizer and following the appropriate steps for your machine. Regular sanitizing, along with proper cleaning, is essential for maintaining the hygiene of your Manitowoc ice machine and ensuring that the ice produced is safe for consumption.

Cleaning the Condenser

The condenser is a vital component of your Manitowoc ice machine, responsible for dissipating heat and ensuring efficient ice production. A clean condenser allows for optimal airflow, leading to efficient operation and preventing the ice machine from overheating. However, dust, dirt, and debris can accumulate on the condenser over time, hindering its performance. Regular cleaning of the condenser is essential for maintaining the efficiency and longevity of your ice machine. Before cleaning the condenser, ensure that the ice machine is turned off and unplugged. This is a crucial safety precaution to prevent electric shock. Locate the condenser unit, which is typically located on the back or bottom of the ice machine. Use a vacuum cleaner with a brush attachment to remove any loose dust or debris from the condenser coils. For more thorough cleaning, you can use a soft-bristled brush to gently scrub the coils. Avoid using any harsh chemicals or abrasive cleaners, as these can damage the condenser. After cleaning, allow the condenser to dry completely before plugging the ice machine back in. Regular cleaning of the condenser will ensure optimal performance of your Manitowoc ice machine, promoting efficient ice production and extending its lifespan.

Ice Thickness Probe Cleaning

The ice thickness probe plays a crucial role in the operation of your Manitowoc ice machine. It accurately measures the thickness of the ice, ensuring that the machine produces ice of the desired size and quality. However, over time, the probe can become coated with mineral deposits, affecting its accuracy and potentially leading to inconsistent ice production. Regular cleaning of the ice thickness probe is essential for maintaining optimal ice quality and extending the life of your ice machine. To clean the probe, start by mixing a solution of Manitowoc ice machine cleaner and water. The recommended ratio is 2 ounces of cleaner to 16 ounces of water. Pour the solution into a container that is large enough to submerge the probe. Carefully remove the ice thickness probe from the ice machine. This may require consulting your ice machine manual for specific instructions. Submerge the probe in the cleaning solution for a few minutes, allowing the cleaner to dissolve any mineral deposits. Use a soft-bristled brush to gently scrub the probe, removing any remaining debris. Rinse the probe thoroughly with clean water to remove any residual cleaner. Allow the probe to air dry completely before reinstalling it in the ice machine. Regular cleaning of the ice thickness probe will ensure that your Manitowoc ice machine continues to produce high-quality ice consistently.

Maintenance Tips

Beyond regular cleaning, several proactive steps can prolong the life and efficiency of your Manitowoc ice machine. First, ensure the water supply to your machine is clean and free of impurities. Consider installing a water filter to remove sediment and contaminants that can negatively impact ice quality and machine performance. Regularly check and replace the water filter as recommended by the manufacturer. Additionally, monitor the condition of the ice bin gasket. A damaged or worn-out gasket can lead to ice leakage and water damage. Inspect the gasket regularly and replace it if necessary. Pay attention to the condenser, the component responsible for removing heat from the refrigerant. A dirty condenser can restrict airflow, leading to reduced efficiency and increased energy consumption. Clean the condenser periodically, following the instructions provided in your ice machine manual. Finally, avoid overloading the ice bin. Allowing ice to build up in the bin can obstruct the ice dispensing mechanism and impede efficient operation. Ensure the bin is emptied regularly, preventing ice from becoming compacted or accumulating beyond its capacity. By following these maintenance tips, you can ensure your Manitowoc ice machine operates reliably and efficiently for years to come.

Troubleshooting

While regular cleaning and maintenance help prevent issues, problems can still arise with your Manitowoc ice machine. If you encounter problems with your machine, it’s crucial to identify the root cause before attempting any repairs. Start by consulting your ice machine manual for troubleshooting guides and common solutions. If the manual doesn’t provide a resolution, consider these common issues and potential solutions⁚ If your machine is producing ice that’s cloudy or discolored, it could indicate a problem with the water quality or a buildup of mineral deposits. Ensure the water supply is clean and free of contaminants. If necessary, use a descaler to remove mineral deposits from the machine’s internal components. If the ice machine is not producing ice, check the power supply and ensure the machine is properly plugged in and switched on. Verify that the water supply valve is open and that water is flowing to the machine. If the ice machine is making unusual noises, such as grinding or banging, it could indicate a mechanical problem with the ice-making mechanism. Inspect the machine for any loose parts or obstructions that might be causing the noise. If the noise persists, contact a qualified technician for assistance. Remember, attempting repairs without proper knowledge can damage the machine and potentially void the warranty. For complex or persistent problems, always consult a qualified technician to ensure safe and efficient operation of your Manitowoc ice machine.

Maintaining a clean and well-functioning Manitowoc ice machine is essential for producing high-quality ice, ensuring food safety, and extending the machine’s lifespan. Regular cleaning and sanitizing, as outlined in this manual, are crucial for preventing bacteria growth and maintaining optimal performance. Following the step-by-step cleaning process ensures thorough cleaning of all machine components. Remember to use only Manitowoc-approved cleaning solutions for optimal results and to avoid damaging the machine. By consistently following these cleaning guidelines, you can ensure that your ice machine operates efficiently and produces pristine ice for your business or home. If you encounter any unexpected issues or require further assistance, consult your ice machine manual or contact a qualified technician for professional guidance.

Be the first to reply